Storage systems

The storage tanks are assembled without complex scaffolding or crane work.

The storage tanks are assembled without complex scaffolding or crane work.

First, a closed ring segment is created, and in the second step the finished ring segment is lifted by using a lifting spindle system and then the next ring segment is mounted.

This technique allows the storage tank to be assembled from top to bottom, which means that extremely short assembly times are possible.

Mounting

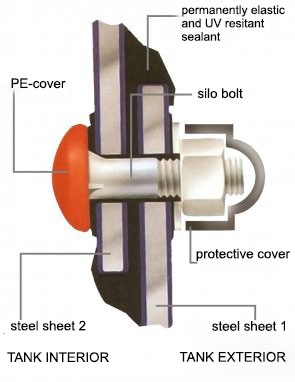

The plate bolting used by means of silo bolts ensures maximum safety, absolute tightness and stability.

Hot-dip galvanised special bolts with polyethylene cap inside. Highly resistant and weatherproof sealing compound with UV protection

The overlap areas at the panel joints are permanently sealed on the inside of the container tank by a special sealing compound. This crush seal ensures that the tank maintains its tightness.

Economical

Low investment costs and minimal maintenance costs speak for the use of a farmatic tank

Sustainable

Thanks to the use of quality materials and optimum coating techniques, farmatic containers are extremely durable. All container parts are fully recyclable

Transportable

The individual components are transported on pallets. Transport dimensions and weights are so low that even larger systems can be transported over long distances without problems and at low cost

Efficient

farmatic containers are erected by experienced fitters within a very short time, all year round. Every project is supervised by farmatic specialist engineers who guarantee fast and trouble-free completion

Flexible

Volume can be increased at any time by adding more or less storeys. This allows the tanks to be adapted to current operating conditions. New pipelines and other installations can be retrofitted without difficulty, even after many years. farmatic tanks can be dismantled and reassembled at a later date, e.g. in the event of a relocation of operations.

Maintenance-free

Our coating systems provide permanent corrosion protection. Maintenance is therefore not required. In the case of special equipment, we recommend interval inspections, which can also be carried out by us within the framework of a service contract.

Accessories

The farmatic container range includes a comprehensive range of container accessories. Different materials and designs are available depending on the respective area of application.

- Equipment and attachments in hot-dip galvanised steel, stainless steel or aluminium

- Roofs in various versions, floors

- Agitators

- Fixed ladders, mantle stairs, spiral stairs, stair towers

- Footbridges, working platforms and podiums

- Sheet steel or aluminium facades with insulation

- Pipe penetrations and pipelines, access hatches

- Over- and underpressure protection